Impregnation

There Holz Brenz srl has always considered wood as a living, ecological and recyclable material, capable of adapting to every housing need faithful to a natural lifestyle, in movement and subject to continuous transformation over time.

It is for this reason that wood, especially if located outdoors and always exposed to atmospheric agents, must be absolutely protected.

Our products are mainly made of coniferous wood and in particular pine because it is more readily available in nature and because the supply areas follow strict reforestation policies.

Thanks to the Autoclave Impregnation process with non-harmful products based on Copper Salts and free from Chromium, Arsenic and Boron, it is possible to obtain a high degree of resistance to attacks by harmful agents such as: Fungi, Mould and Rot, making it ideal for use in outdoor spaces.

It should be remembered that the durability of a wooden product depends both on the impregnation and on a correct design and installation in order to protect the wood from contact with water while allowing easy drainage.

Our Autoclaves

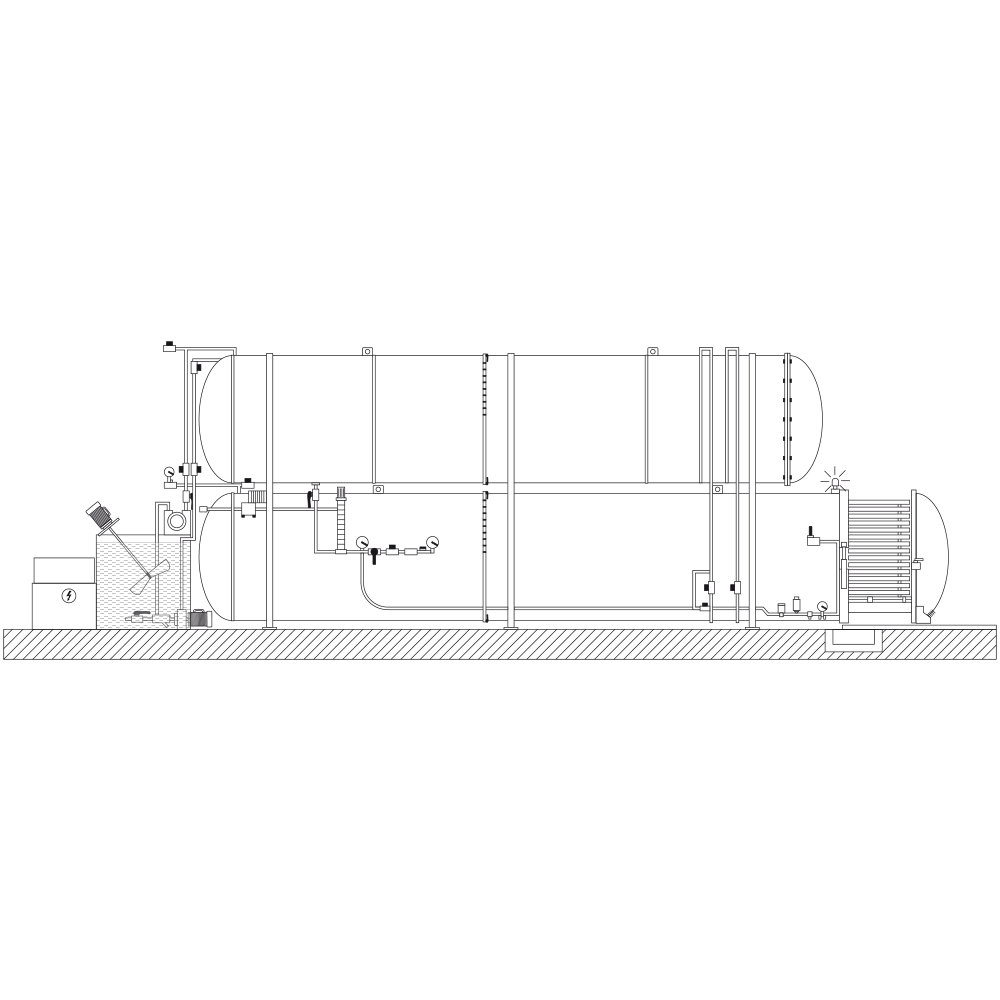

Our company has a warehouse with an average annual stock of 5,000 cubic meters of wood that we treat with the impregnation process in 2 Autoclave Machines capable of responding to every need of the market and therefore to our customers.

The “Core Business” impregnation we use is the most technological and safe to date as it uses state-of-the-art systems that comply with current European regulations.

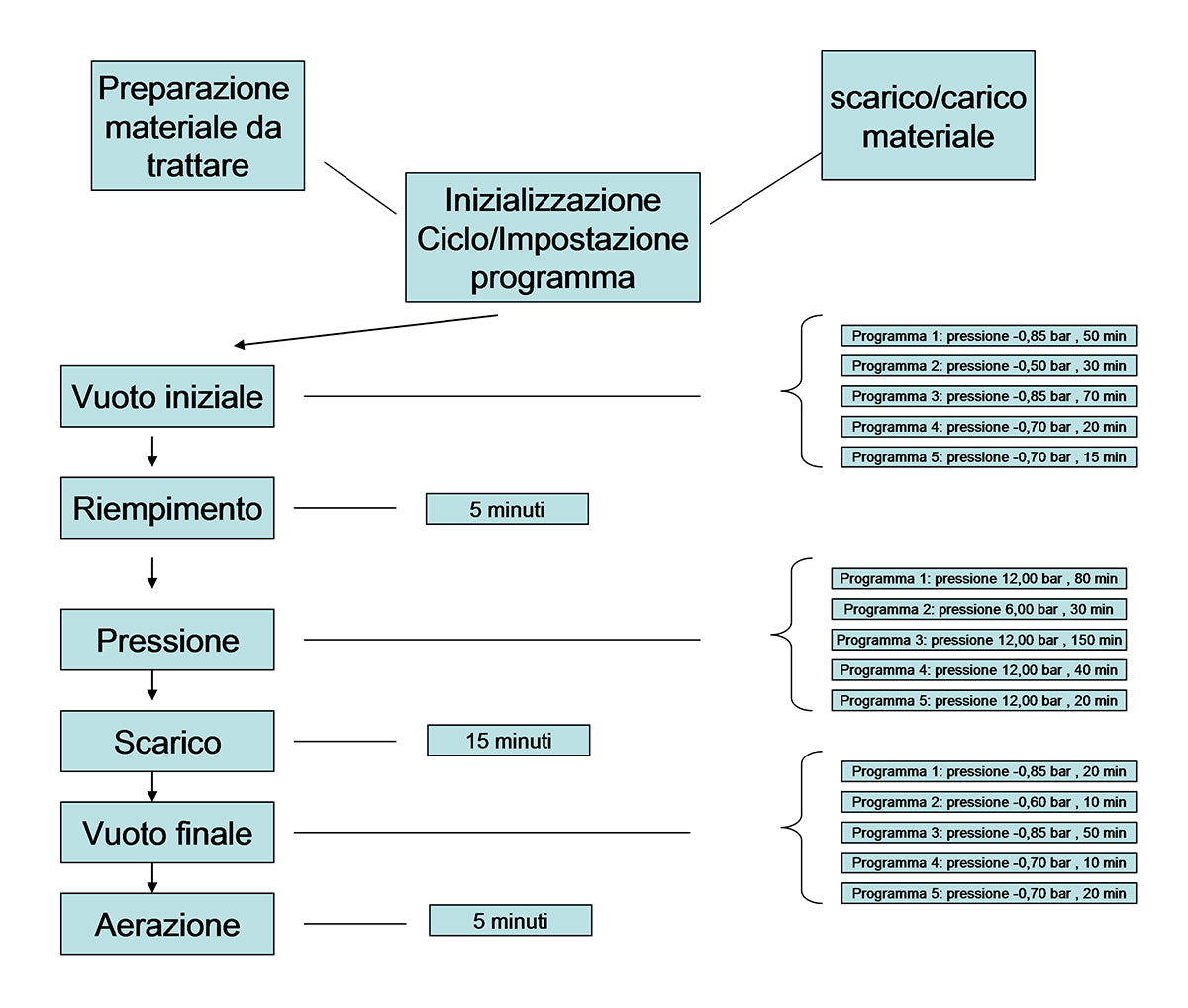

The six phases of the vacuum impregnation cycle of wood

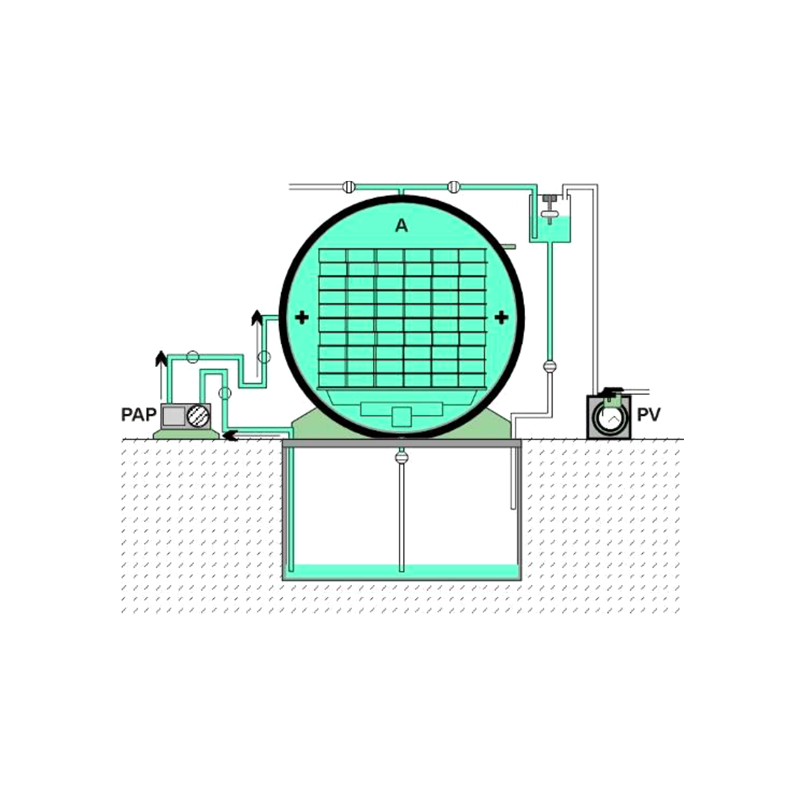

Phase 1: Initial vacuum

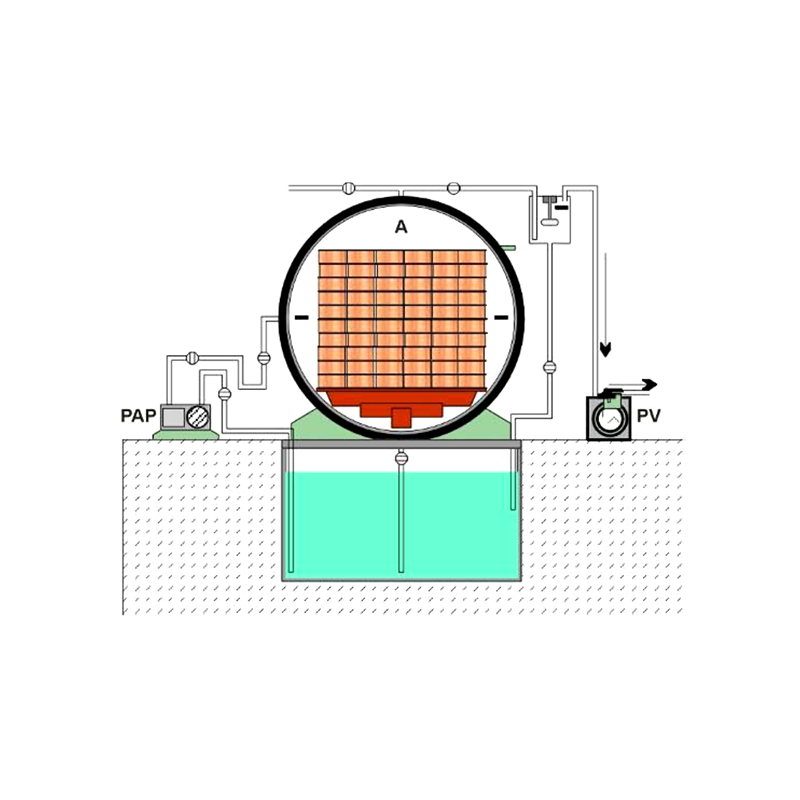

The wooden stack, once positioned on the motorized trolley of the autoclave, is inserted into the system to start the cycle.

The hermetic closing of the door allows the machine to start the treatment by activating the vacuum pump.

This phase, very important to make the penetration of the preservative more effective, frees the wood tracheids from the air, generating a "depression" that will allow the wood to "suck" the preservative solution inside itself.

The vacuum period can vary from 15 to 70 minutes depending on the characteristics of the wood.

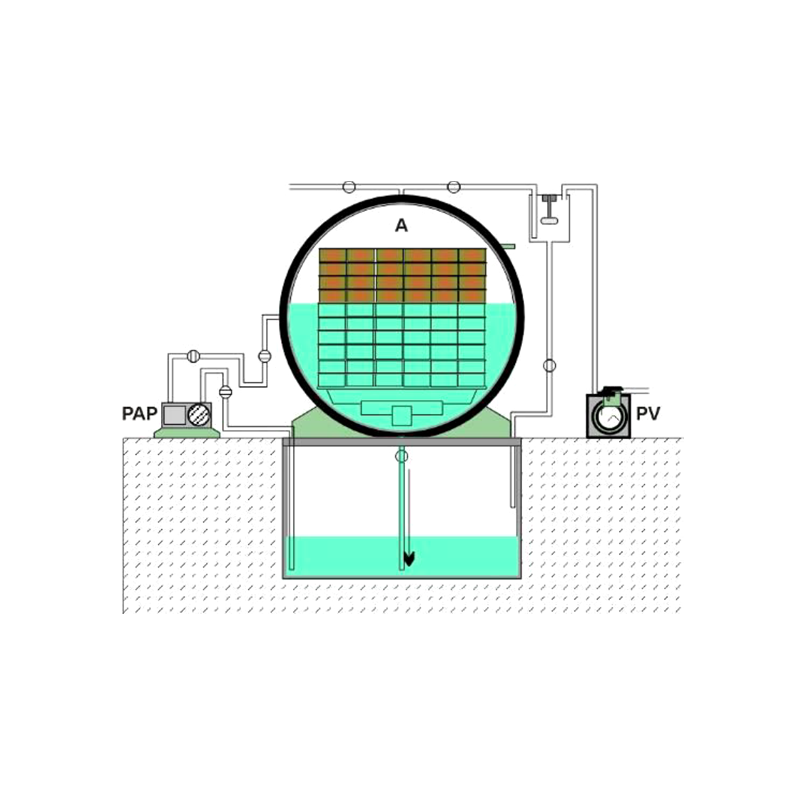

Phase 2: Filling

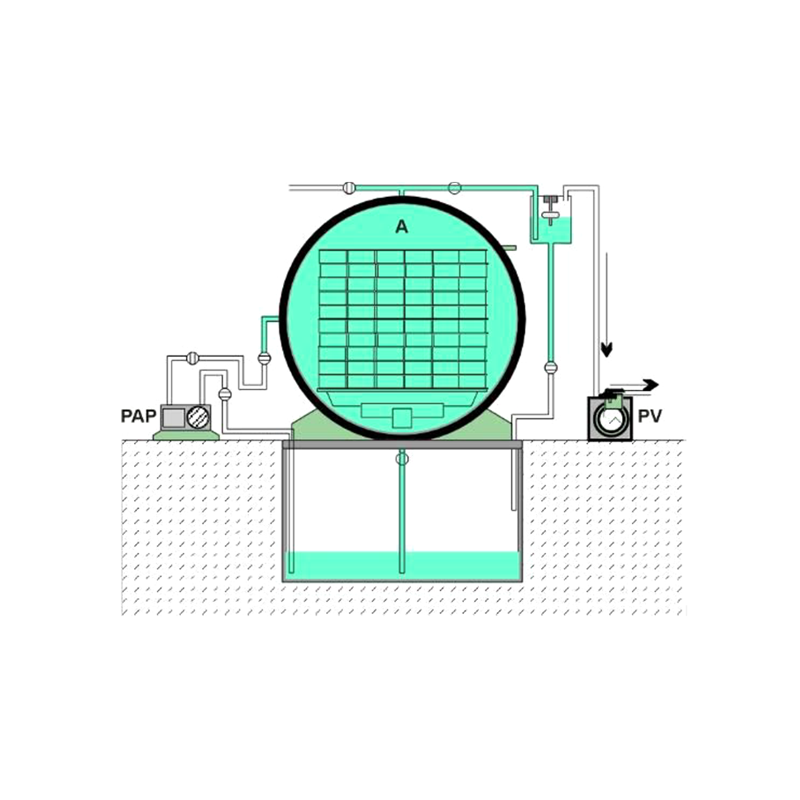

Once the first phase is completed, the depression is used to convey the treatment solution from the upper tank to the lower autoclave.

The filling phase of the autoclave (35,000 Lt) consists in the complete immersion of the underlying material in the impregnating substance and is regulated by a special level sensor that sends a control signal to the system's computer.

Phase 3: Applying pressure

In this phase the actual impregnation of the material takes place, in fact the desired pressure levels are reached which have the task of "forcing" the solution into the wood.

The operation of the pressure pump can vary from 30 to 180 minutes depending on the characteristics of the material.

The combined action with the vacuum will allow the active ingredients to fix themselves deeply to ensure long-lasting protection.

Step 4: Draining the solution

Once the actual treatment phases are completed, the solution not absorbed by the wood returns to the tank above through a drain valve positioned on the bottom of the autoclave.

All unabsorbed solution is available for reuse without any waste.